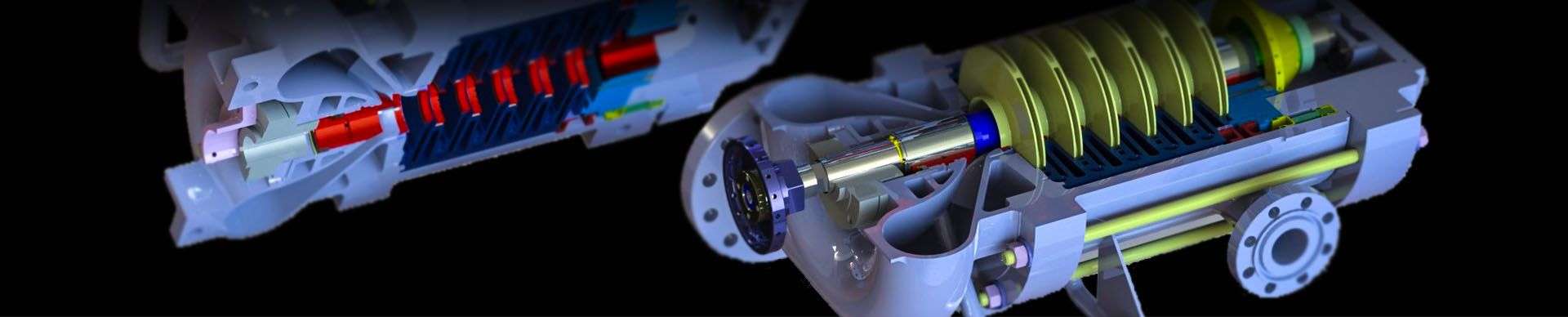

Conhagen Rotating Equipment Vibration Analysis

The experience to analyze and diagnose your vibration concerns

Mechanical vibration may or may not be an indication of problematic operation in static or rotating equipment. Most systems have to live with some vibration under normal operating conditions and end-users are encouraged to monitor their crucial equipment to ensure that these levels do not exceed operational thresholds. Often times, vibration which is normal can gradually become detrimental to a system. Conhagen has the expertise and the experience to analyze and diagnose your vibration concerns and determine the best means of mitigating abnormal vibration levels.

Our experience is that many factors can contribute to vibration, including:

- Rotordynamic issues

- Component wear

- Blade passing frequencies

- Pipe strain and alignment issues

- Flow cavitation and acoustic interaction

- Transient heating

- Installation errors

Generally, the cause of unwanted vibration is not obvious, and the vibration mechanisms can become coupled, making it more difficult to find a root cause. Conhagen’s engineering group uses sound practices to sort through the noise and find the source of the problem.

The use of eddy-current probes and/or accelerometers allows Conhagen to identify the driving frequency of the vibration and the point from which it originates. If necessary, modal impact studies can also be conducted to identify the system fundamental frequencies, modal damping, and mode shapes.

Vibration Analysis Quote or Question:

Fill out the form below to speak with a Conhagen expert or call us:

- Louisiana: (504) 471-9958

- Texas: (409) 938-4226 | (800) 872-5187

- West Coast: (707) 746-4840